working on primarily honda CB's the last few years, I've become quite versed in it's language. sure, there are varying dialects but never straying to far from it's core, and I find myself referencing manuals less and less.

Wednesday, September 25, 2013

Saturday, September 21, 2013

Thursday, September 19, 2013

CB750 build continues

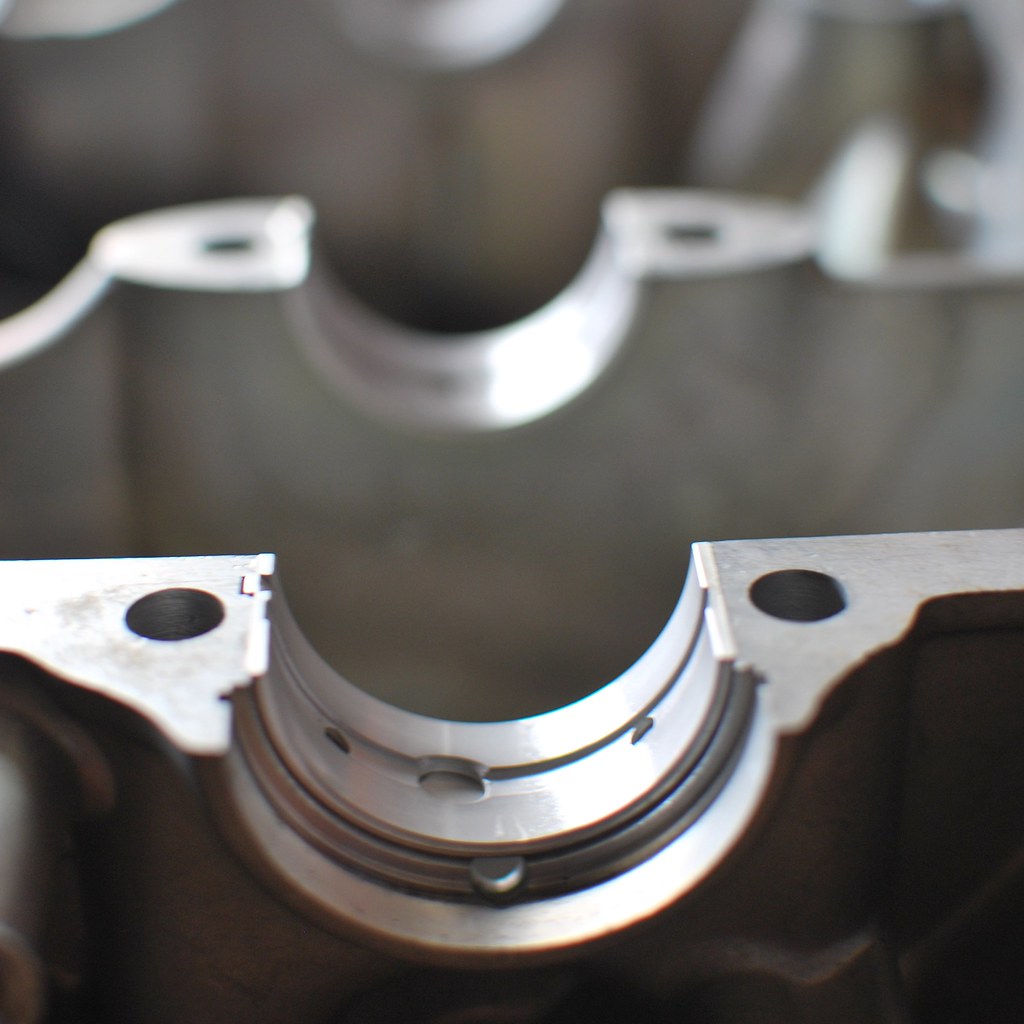

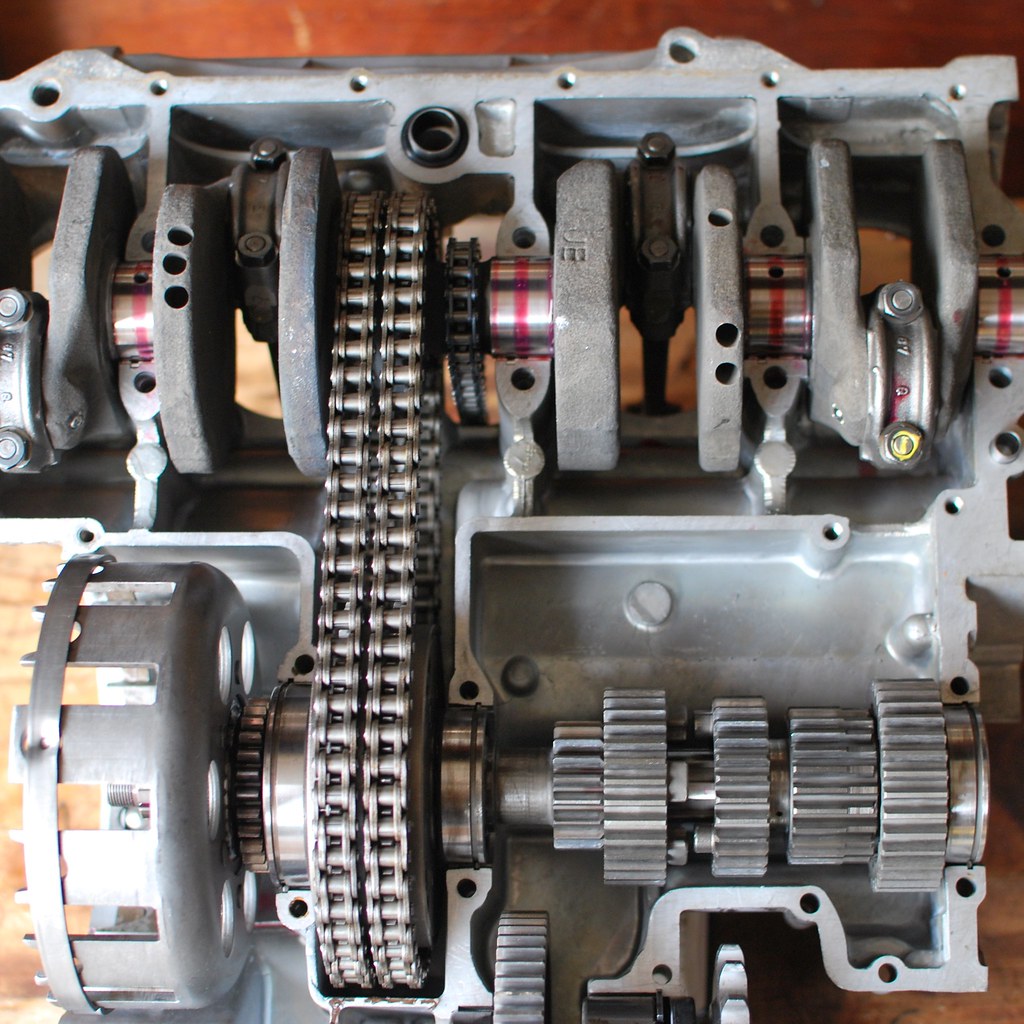

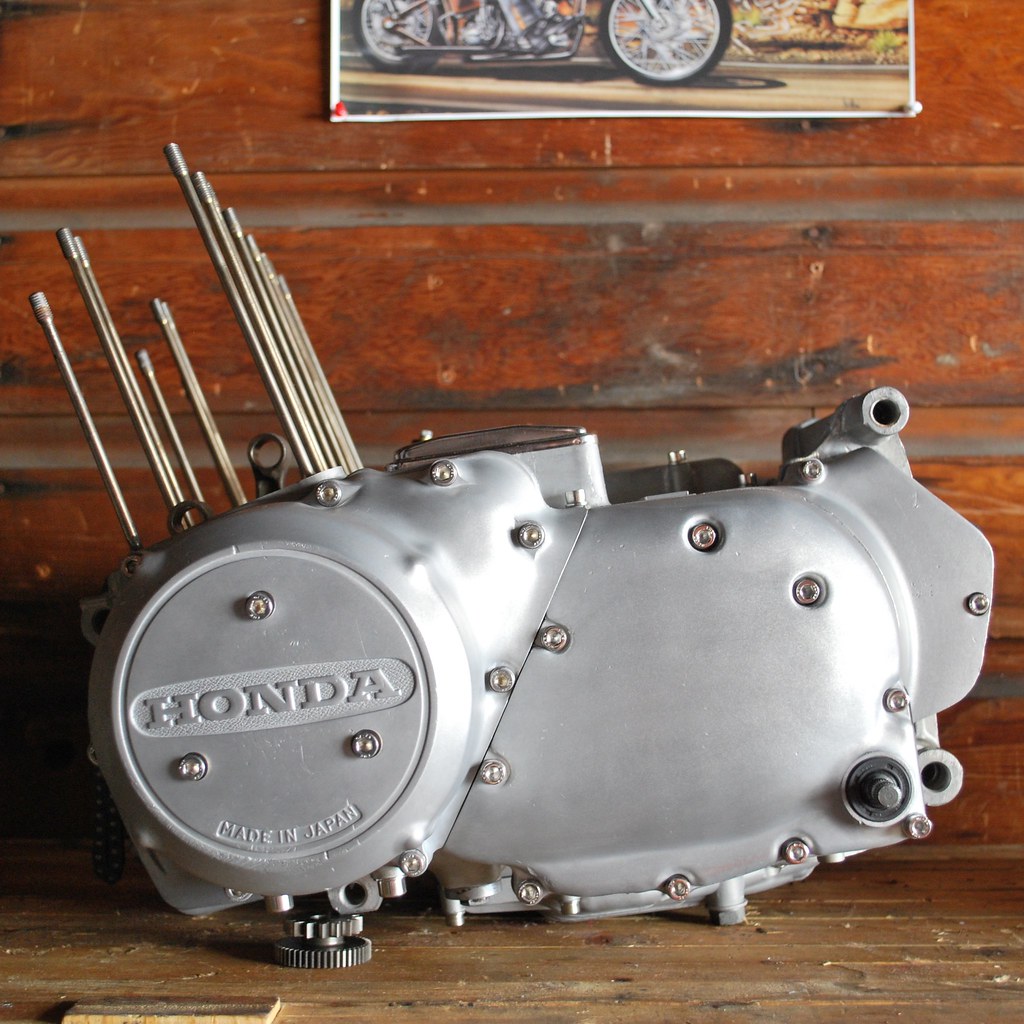

with a few shipping issue out of the way, my crankshaft main bearings showed up successfully on monday afternoon. it didn't take long to plastiguage for clearances, drop in the transmission, shift drum and button up the bottom end. tuesday, I tackled the engine on all fronts, installing the stator, clutch and shifter assembly. once I have a decent set of cylinders, the rest of the build should all fall together.

happenings around the shop

the XS650 build is continuing on it's slow and stead pace. problems with the stock head gasket has prompted a custom made copper head gasket. with the gasket on it's way, the build will nears completion.

m.'s CB750 had a few charging issues that were sorted out, but he was still going through batteries fast. the original builder of the bike had the wiring set up with the headlight, tail light, speedo and tach lights all on once you turn the key position to on. m.'s 3 amp/hour battery didn't stand a chance handling such a huge draw. I installed a waterproof accessory switch, so that with the key switched to the on position, the only draw are the coils and the pamco ignition (0.020 amps). With the accessory switch, all the lights can be saved for after dark.

Labels:

cafe,

CB750,

electrical,

HUGHSHANDBUILT,

pamco,

PMA,

rephase,

XS650

Thursday, July 18, 2013

CB750 engine rebuild

for the last year, I have been picking away at my own person CB750 project. this frankenbike is a build up mostly from accumulated parts I had lying around, along with a few purchases I have made. I decided a few days back to do a full engine rebuild. the engine's primary chains were pretty sloppy, the top end was quite weepy and since I am doing a ground up bike build, I wanted peace of mind that the engine is solid.

after quickly cleaning up the head, I refaced the valves and cut new valves seats.

after quickly cleaning up the head, I refaced the valves and cut new valves seats.

Once the valves were refaced, I back cut the valves with a 30 degree angle above the contact area to remove the lip and allow better flow.

100% seal on the vacuum test.

I finished the head off with a quick resurface to get a great seal with the head gasket.

I am considering cleaning up the combustion chamber and ports a wee bit, but for now, it's onwards to the bottom end...

new work rolls in

last week, M. dropped off his '72 CB750 with a small list of troublesome gremlins: a leaky shifter side cover, an exhausted charging system, and an antiquated ignition system.

the pamco ignition rotor proved to be a little troublesome on installation. this was due to too loose of a tolerance where the rotor installs on the stock advance mechanism. with some manual machining, the two parts mated up perfectly.

( the rotor on my personal CB750. Notch is 0.160" wide)

(M.'s rotor is 0.008" narrower. too narrow for the advance weights to fit in)

also on installation, I did notice that M.'s ignition advance springs were not fully working. as they do not make the springs anymore, I'll be heading to the salvage yard this weekend to dig up a pair in better condition.

Wednesday, June 12, 2013

CB350F top end rebuild

I finally got around to finishing off the CB350F top end rebuild last week. I gave the cylinder head a quick (re)surface, I deglazed the cylinders with a coarser grit flex hone, and made sure to seal up the head gasket with Copper Spray-A-Gasket. I thought to add a little Hondabond on the troublesome jets for good measure.

The rings have seated, the jets are, um, jetting! and the engine is oil tight again! Next up, rebuilding a troublesome clutch....

XS650 rebuild continues

progress continues on the XS650 rebuild. While the crank and cam being shipped out to Hugh's Handuilt, top end progress continues on the head and cylinders....

After the new Kibblewhite valve guides are installed, the I.D. must be taken down to size. Gene showing me the ropes as we hone down the Kibblewhite valve guides to perfect clearances.

After the guides were dialed in, the seats were cut and the head resurfaced.

Here, the cylinders are being rebored up to 750cc.

Labels:

HUGHSHANDBUILT,

machine shop,

machining,

rebore,

XS650,

YAMAHA

Monday, May 13, 2013

Back to the Grinding Stone

Today I got word that my position at the engine machine shop will be (more) permanent. Although it is only part-time for now, it's a huge opportunity for me to challenge myself as I hone my engine building/machining skills. The staff I get to work with are truly amazing and genuine. Because of them, I look forward to coming in every morning and seeing what the day has in store. Love my job.

The Infamous Leak

The plan this week is for an educated attack; Armed with insight, Hondabond and Copper Spray a Gasket.

Tuesday, May 7, 2013

Wheel Rebuild

Converting the CB750's front brake to drum has been an interesting challenge. I'll be installing all new bearings once everything is cleaned up, along with new spokes and a pair of alloy shouldered rims. I always digged the front drum brake on the 750 prototype. Too bad it didn't stick. But maybe that was the problem.

Thursday, May 2, 2013

Prime time

After trying different combinations of primer and paint, I've found a solid match that I'm happy with and have started priming the CB750 frame and misc parts. The weather looks to be pretty stellar this weekend so I'll get the base paint on in the next couple days.

Wednesday, May 1, 2013

Waiting For The Paint To Dry

Tuesday, April 30, 2013

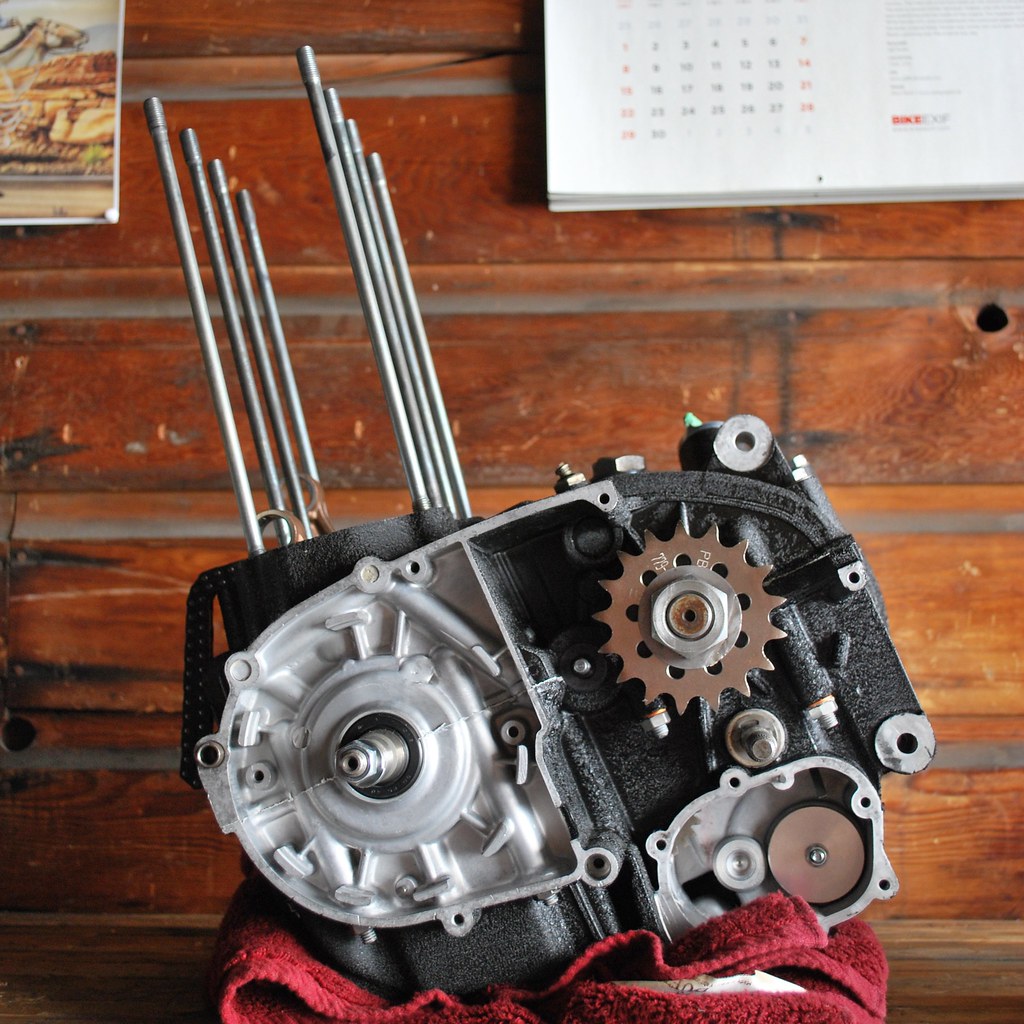

Launch of the Apollo

-Cam and crank will be shipped to Hugh's for a rephase to 277

-Pamco ignition

-700cc overbore

-Resurfaced head and valve job

-Aftermarket oil filter

-Permanent magnetic alternator

-Swapping out transmission with a later model including 5th gear overdrive

-Hydraulic clutch

-2" sump extension

-New gaskets and oil seals

Once the engine is entirely apart, I'll be able to inspect the bearings, valve guides and any other bits that made need replacing.

Stay tuned.

Subscribe to:

Comments (Atom)